These commands can be entered interactively or by script via the

controller serial port. To communicate interactively with the controller, use

a standard serial terminal program such as HyperTerminal or TeraTerm under windows,

or minicom under Linux.

All commands are a single command letter with up to two integer numeric arguments

seperated by spaces. Commands are case-sensitive (ie. 'G' is not the same

as 'g'). Here is an example command session showing the meaning of each command

and various syntax:

AVR Motor Controller Commands |

Notes |

General Commands |

|

Description |

Cmd |

Arg0 |

Arg1 |

|

| Help |

'?' |

. |

. |

Displays on-line help for available commands |

| Select Motor |

's' |

motor# |

. |

Select motor to control (1 or 2) |

| Motor Control Mode |

'm' |

mode |

. |

mode=0: Control off (motors disabled)

mode=1: Position control

mode=2: Velocity control (use 'v' command to set velocity)

mode=3: Cross-linked control |

| Goto Position (PID) |

'g' |

position [tics] |

. |

Drives selected motor to requested position under direct PID control. |

| Goto Position (PID) |

'G' |

pos1 [tics] |

pos2 [tics] |

Drives both motors simulanteously to requested positions under direct

PID control (NOTE: pos1 need not equal pos2). |

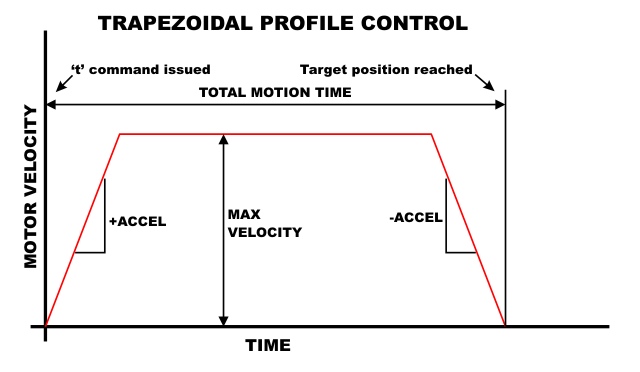

| Goto Position (Prof) |

't' |

position [tics] |

. |

Drives selected motor to requested position under PID+PROFILE control.

Uses trapezoidal motion profile. |

| Goto Position (Prof) |

'T' |

pos1 [tics] |

pos2 [tics] |

Drives both motors simulanteously to requested positions under PID+PROFILE

control. Uses trapezoidal motion profile. |

| Reset Encoders |

'z' |

pos1 [tics] |

pos2 [tics] |

Resets the encoder counters. Allows reassigning the current physical

position to user-selected encoder values. If no arguments are specified

then encoders reset to zero. |

| Read Motor Current |

'c' |

. |

. |

Returns motor current in mA (if current sensing is connected) |

Configuration Print/Read/Write |

|

| Config Print |

'L' |

. |

. |

Prints settings and coefficients that are currently active. |

| Config Write |

'w' |

. |

. |

Stores all current settings and coefficients into EEPROM. The settings

are automatically loaded at power-on. |

| Config Load |

'l' |

. |

. |

Load settings and coefficients from EEPROM. Restores all settings to

those last saved with 'w' command. |

PID Tuning Assistance |

|

| Record Response |

'r' |

. |

. |

Sets currently selected motor for response recording. Response recording

records the actual motor trajectory for the first 200points after the

next 'g' command. |

| Upload Response |

'R' |

. |

. |

Returns the recorded motor trajectory data from 'r' command. Each data

point is the motor position (encoder value) as it approached the target

position requested by the 'g' command. |

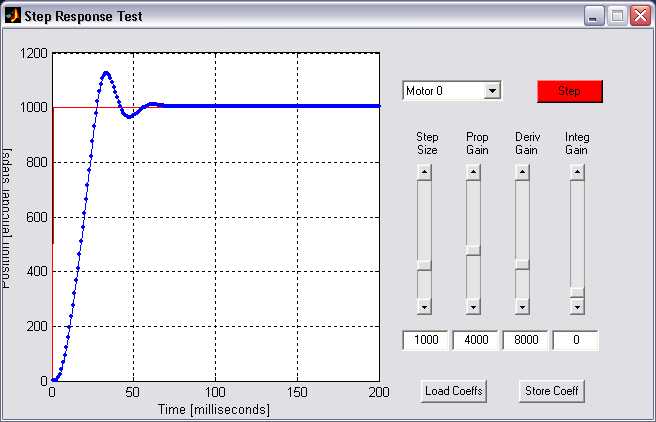

| Step Response Test |

'f' |

. |

. |

Runs automatic motor step-response test. |

Trapezoidal-Profile Controller Settings |

|

| Set Max Velocity |

'v' |

vel |

. |

Sets the maximum velocity to be used under trapezoidal profile control.

Also used in velocity control mode to set desired velocity. |

| Set Max Acceleration |

'a' |

accel |

. |

Sets the acceleration to be used under trapezoidal profile control |

PID Controller Settings |

|

| Set Prop. Gain |

'P' |

Kp |

. |

Sets the Proportional gain for currently selected motor [units TBD] |

| Set Integral Gain |

'I' |

Ki |

. |

Sets the Integral gain for currently selected motor [units TBD] |

| Set Derivative Gain |

'D' |

Kd |

. |

Sets the Derivative gain for currently selected motor [units TBD] |

| Set Windup Max |

'W' |

wm |

. |

Sets the maximum value for integral error (clamping value) |

| Set Output Max |

'M' |

om |

. |

Sets the maximum motor drive level [PWM units, out of 1200] |

| Set Deadzone |

'Z' |

dz |

. |

Sets the minimum motor drive level [PWM units, out of 1200]

Below this level, the motor power will be clamped to zero. |

System Test Commands |

|

| Encoder Test |

'e' |

. |

. |

Prints encoder count value for both motors. Press any key to exit. |

| Motor Driver Test |

'q' |

. |

. |

Runs motors in ramp test pattern in both directions. Press RESET to

exit. |

| This command list current

as of firmware V1.6g, but is subject to change. |